PerfStudio: Monitoring, Diagnostics and Optimization Software

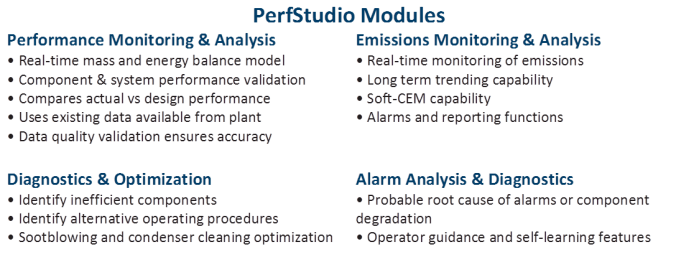

PerfStudio is a suite of integrated software modules designed to perform real-time monitoring, analysis, diagnosis and optimization of each critical power generation equipment or system. PerfStudio provides real-time information for operators and engineering staff, plant management, and corporate executives to optimize plant performance, heat rate, efficiency, reliability and emissions. PerfStudio uses a complete thermodynamic mass and heat balance of the plant cycle to accurately calculate the true performance of each component and compares this to the expected design performance for each load, fuel and operating condition. Any difference between actual and expected design performance can indicate an opportunity for performance improvement or degradation of equipment that may impact reliability. PerfStudio can be used on fossil-fired steam plants, combined-cycle plants or combined heat and power applications.

Monitor Benefits of PerfStudio Suite

-

- Performance/efficiency of key equipment and systems against design

- Emissions levels and trends to ensure compliance

- Detect equipment anomalies and degradation to improve reliability and plan outages

- Trending for anomalies

- Degradation of sensors

- Diagnose

- Equipment or component inefficiencies

- Equipment failures or degradation

- Probable root causes of component degradation and megawatt losses

- Optimize

- Run “what-ifs” to determine best-achievable operation for heat rate, emissions and capacity output

- Sootblowing and condenser cleaning system operation to improve efficiency